Tool Design Engineer Resume Guide

Tool design engineers create and develop tools that are used in the manufacturing process. They use Computer Aided Design (CAD) systems to design, analyze, simulate and optimize the tooling components before they are created physically. They also research new technologies or processes for creating more efficient designs while ensuring safety standards are met.

You have the creativity and technical know-how to design tools that can revolutionize the industry. But hiring managers won’t recognize your potential unless you make yourself known with a resume that highlights all of your achievements.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

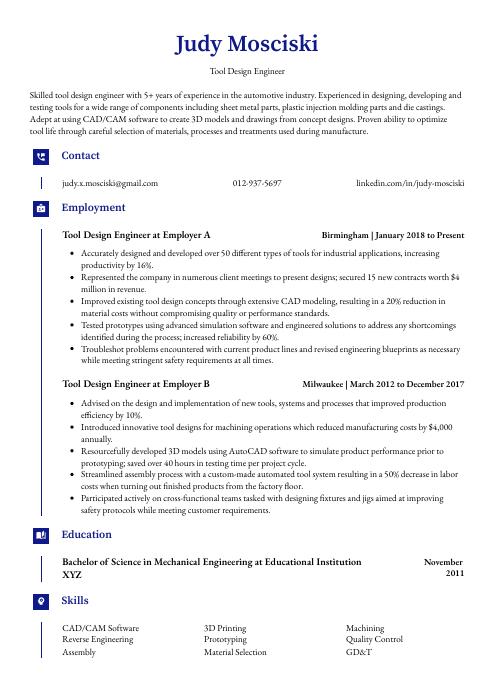

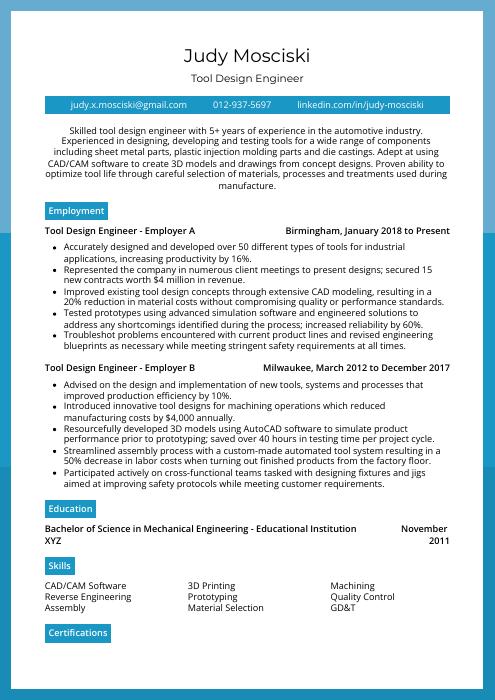

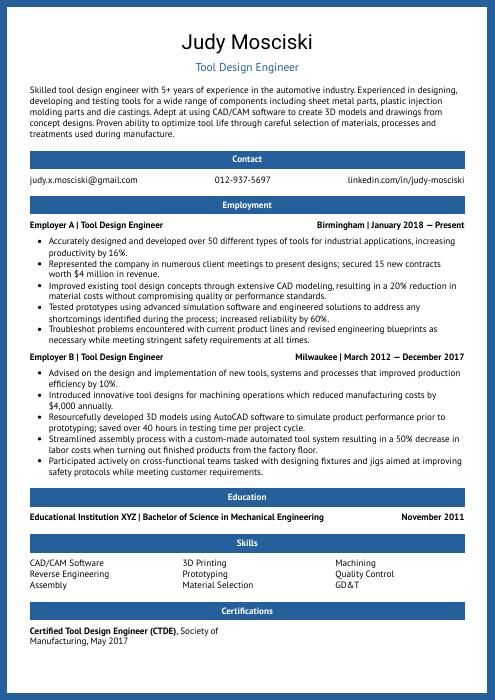

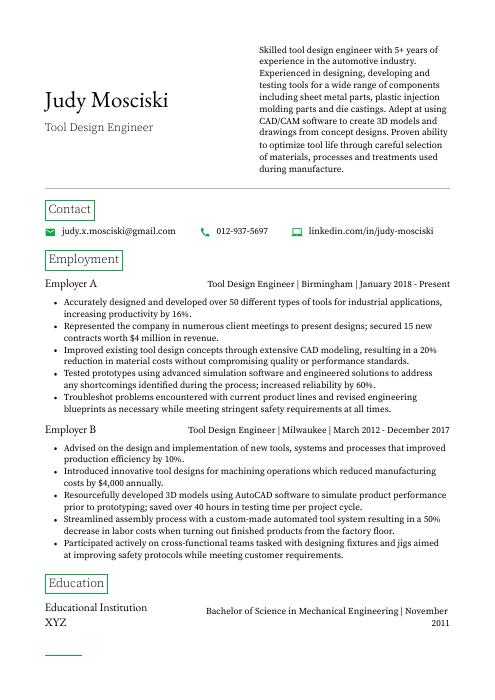

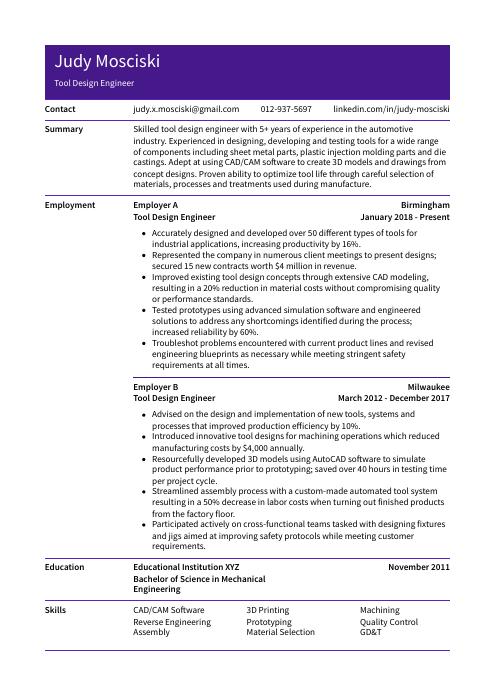

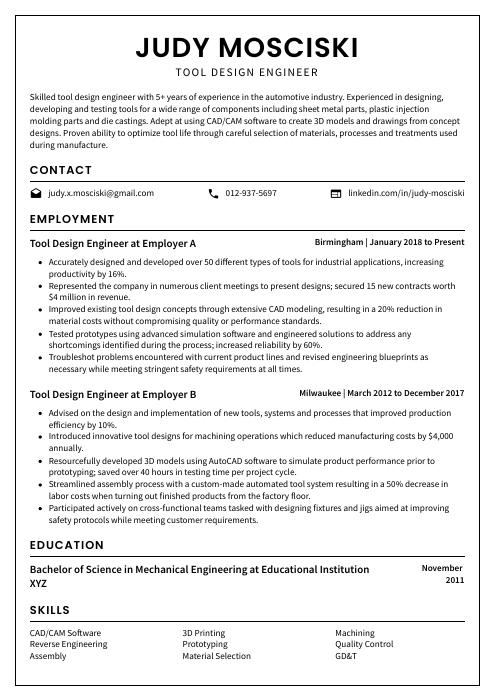

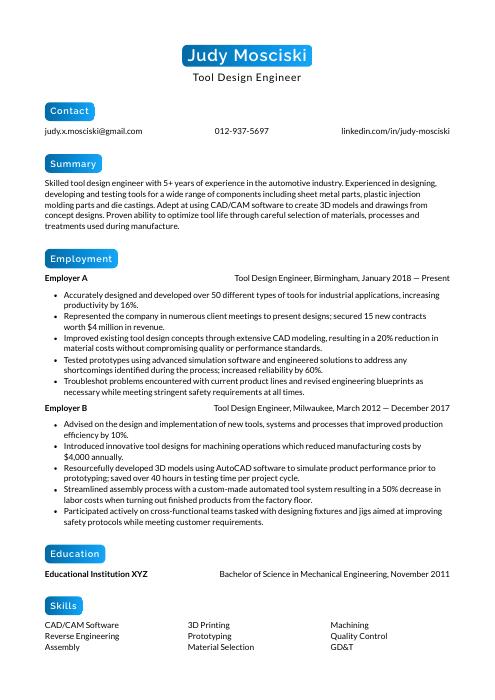

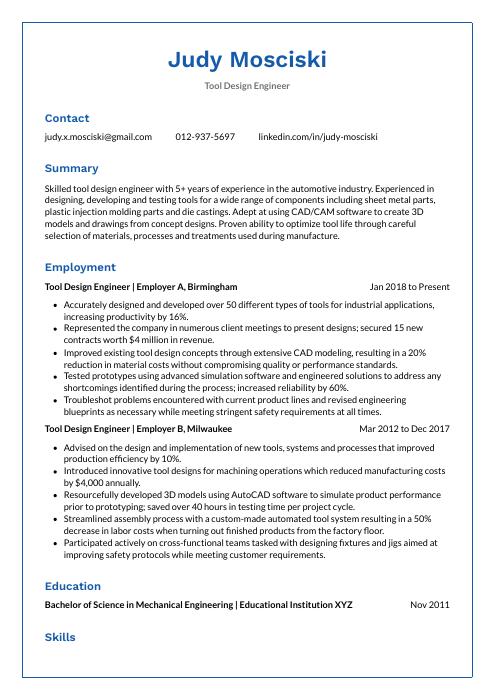

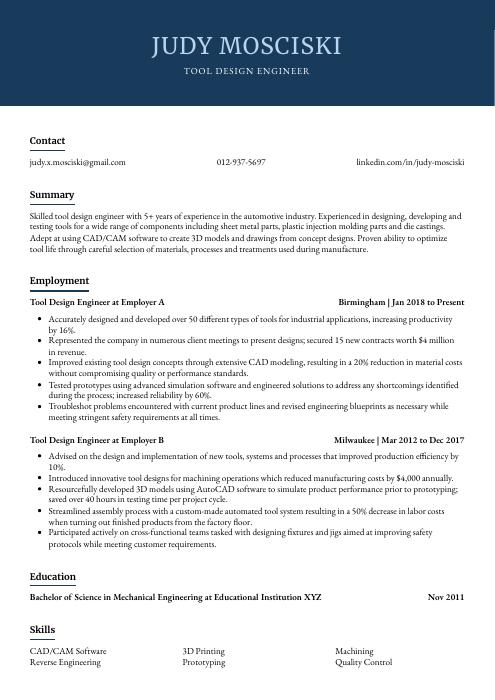

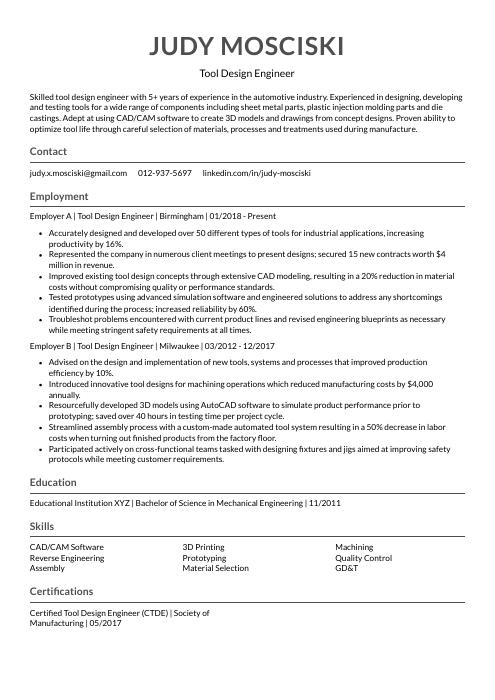

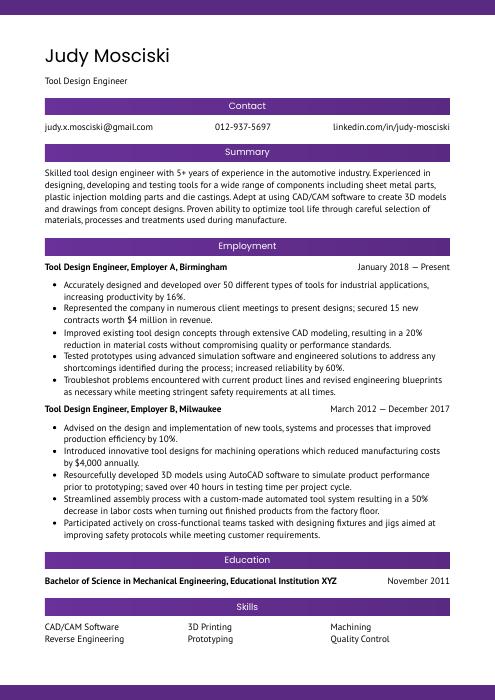

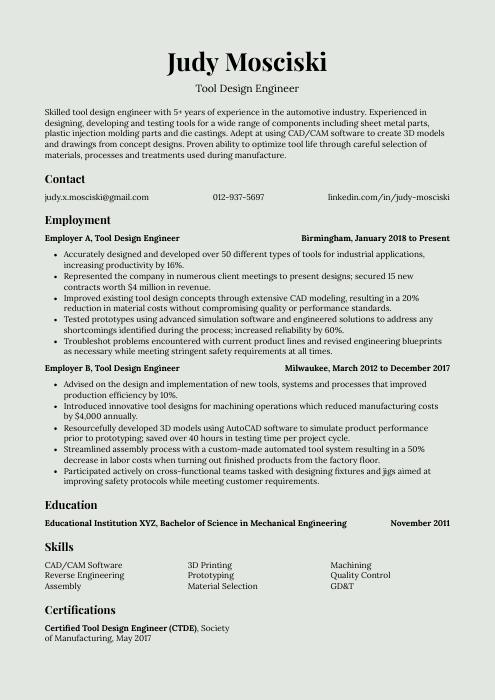

Tool Design Engineer Resume Sample

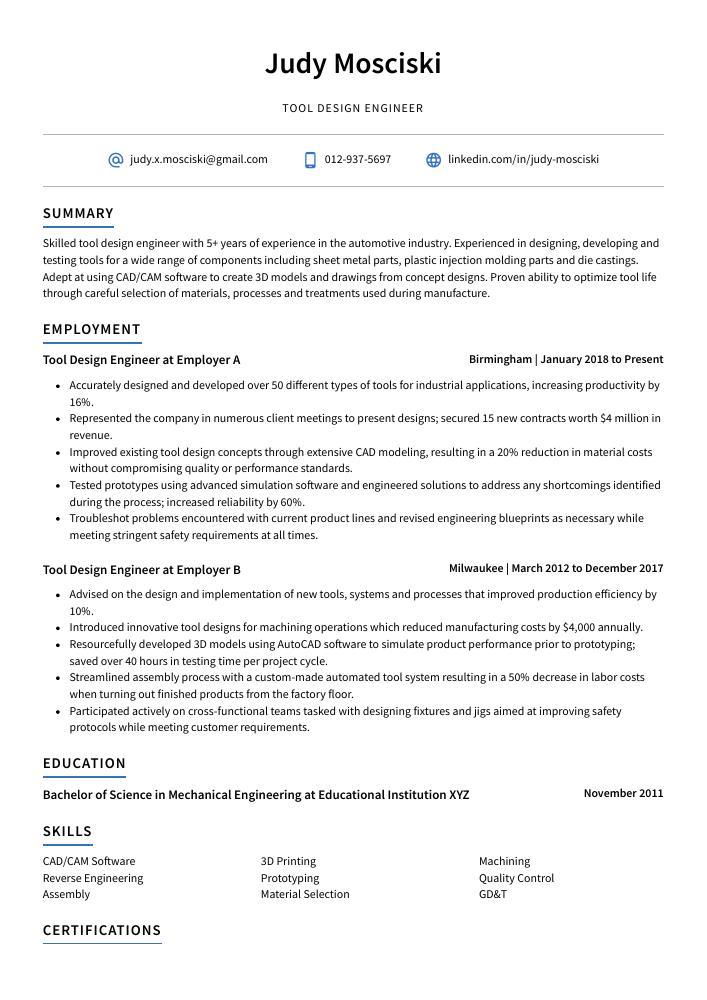

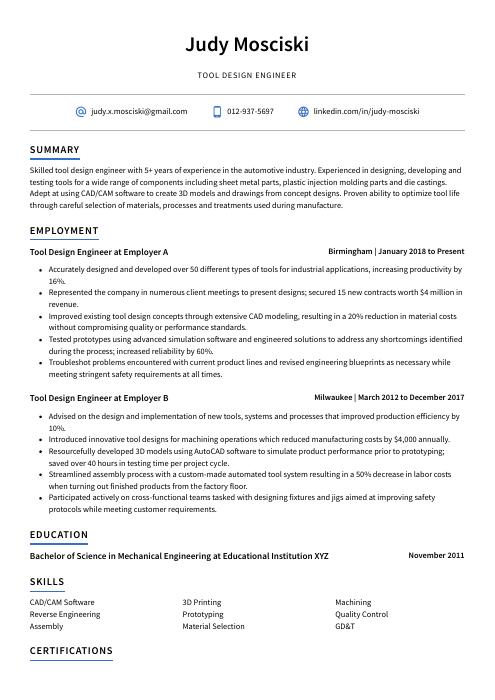

Judy Mosciski

Tool Design Engineer

[email protected]

012-937-5697

linkedin.com/in/judy-mosciski

Summary

Skilled tool design engineer with 5+ years of experience in the automotive industry. Experienced in designing, developing and testing tools for a wide range of components including sheet metal parts, plastic injection molding parts and die castings. Adept at using CAD/CAM software to create 3D models and drawings from concept designs. Proven ability to optimize tool life through careful selection of materials, processes and treatments used during manufacture.

Experience

Tool Design Engineer, Employer A

Birmingham, Jan 2018 – Present

- Accurately designed and developed over 50 different types of tools for industrial applications, increasing productivity by 16%.

- Represented the company in numerous client meetings to present designs; secured 15 new contracts worth $4 million in revenue.

- Improved existing tool design concepts through extensive CAD modeling, resulting in a 20% reduction in material costs without compromising quality or performance standards.

- Tested prototypes using advanced simulation software and engineered solutions to address any shortcomings identified during the process; increased reliability by 60%.

- Troubleshot problems encountered with current product lines and revised engineering blueprints as necessary while meeting stringent safety requirements at all times.

Tool Design Engineer, Employer B

Milwaukee, Mar 2012 – Dec 2017

- Advised on the design and implementation of new tools, systems and processes that improved production efficiency by 10%.

- Introduced innovative tool designs for machining operations which reduced manufacturing costs by $4,000 annually.

- Resourcefully developed 3D models using AutoCAD software to simulate product performance prior to prototyping; saved over 40 hours in testing time per project cycle.

- Streamlined assembly process with a custom-made automated tool system resulting in a 50% decrease in labor costs when turning out finished products from the factory floor.

- Participated actively on cross-functional teams tasked with designing fixtures and jigs aimed at improving safety protocols while meeting customer requirements.

Skills

- CAD/CAM Software

- 3D Printing

- Machining

- Reverse Engineering

- Prototyping

- Quality Control

- Assembly

- Material Selection

- GD&T

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Tool Design Engineer (CTDE)

Society of Manufacturing

May 2017

1. Summary / Objective

A resume summary for a tool design engineer should be concise yet compelling. It should highlight your technical skills and experience, as well as the results you have achieved in previous roles. For example, you could mention how many years of experience you have designing tools for manufacturing processes; any certifications or awards related to this field that you possess; and notable accomplishments such as reducing production costs by 20% through improved designs.

Below are some resume summary examples:

Well-rounded tool design engineer with 5+ years of experience building and testing prototypes while developing innovative tooling solutions. Skilled in using CAD/CAM software to create 2D/3D models, analyze stress points, and optimize mechanical systems. Seeking to join ABC Tech to utilize knowledge of material science principles and machining processes for creating cost-effective designs that are compliant with industry standards.

Dependable tool design engineer with 5+ years of experience in designing and testing automated tools, dies, molds, jigs and fixtures. Skilled at optimizing production efficiency through innovative solutions. At XYZ Corporation increased productivity by 40% via the development of a specialized tooling system that dramatically reduced downtime for repairs. Seeking to bring this expertise to ABC Tech’s team as a Tool Design Engineer.

Proficient tool design engineer with 5+ years of experience in creating and designing tools for the automotive industry. Specializing in CAD/CAM software, manufacturing processes, and 3D printing techniques. Adept at developing creative solutions to complex problems while working closely with other departments within the organization. At XYZ Inc., designed a cost-effective tooling solution that decreased production time by 25%.

Hard-working tool design engineer with over 7 years of experience creating and developing tooling processes for the manufacturing industry. Extensive knowledge in CAD technology, CNC programming, and machine shop operations. At XYZ Company, successfully designed custom tools that increased productivity by 25% while reducing costs by 30%. Seeking to leverage expertise at ABC Corporation to help streamline production processes.

Accomplished tool design engineer with 10+ years of experience in mechanical engineering and tooling. Highly adept at designing, developing, and testing tools for various industrial applications. A proven record of success in optimizing production processes to reduce costs while increasing safety and quality standards. Seeking to join ABC Tech as a Tool Design Engineer where I can utilize my strong technical skillset.

Passionate and highly experienced tool design engineer with 8+ years of experience in the automotive industry. Highly proficient at designing complex tools and fixtures to support efficient production, while emphasizing quality assurance. At XYZ, designed 15 new jigs and fixtures that improved productivity by 20%. Achieved a 100% on-time delivery rate for all projects completed over 5 years.

Detail-oriented tool design engineer with 10+ years of experience in designing and developing tools for the automotive industry. Experienced in both manual and automated tool development processes, with a proven record of successful projects completed on time and within budget. Skilled at using CAD software to create designs that are cost-effective while maintaining high quality standards.

Driven tool design engineer with 5+ years of experience designing and developing tools for use in the manufacturing process. Skilled at creating CAD models, optimizing designs to reduce costs, and troubleshooting existing tooling systems. Seeking a role as a Tool Design Engineer at ABC Company where I can contribute my expertise in streamlining processes and increasing productivity.

2. Experience / Employment

In the experience section, you should list your past employment history in reverse chronological order. Stick to bullet points when describing what you did; this makes it easier for the reader to take in the information quickly.

When writing about each role, be sure to provide detail and quantifiable results where possible. For example, instead of saying “Designed tools,” you could say “Developed 3D CAD models for prototype tool designs that led to a 30% reduction in production costs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Constructed

- Fabricated

- Programmed

- Assembled

- Tested

- Debugged

- Calibrated

- Analyzed

- Optimized

- Documented

- Troubleshot

- Improved

- Monitored

- Inspected

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Designed 50+ production tools and systems for manufacturing facilities, incorporating cost-effective solutions to improve workflow efficiency by 15%.

- Effectively communicated with cross-functional teams in order to gain an understanding of their needs; developed user guides to ensure proper tool operation.

- Spearheaded the development of a new automation system that increased process accuracy and reduced lead times by 25%, saving $30,000 annually in labor costs.

- Formulated detailed design plans for production tools including die casting molds, injection molding dies and other components according to customer specifications within tight deadlines; completed projects ahead of schedule on 4 occasions during tenure at company X.

- Expedited the testing phase using 3D simulations & prototypes which resulted in higher quality products being delivered faster compared to industry standards (+20% reduction).

- Consistently developed and tested over 100+ tools used in manufacturing processes, resulting in a 15% increase in overall production efficiency.

- Inspected molds and dies to ensure product quality and customer satisfaction; reduced reject rate by 25%.

- Monitored tool performance during different stages of the assembly process for any malfunctioning components or defects; identified problems before they escalated into major issues saving 500 man-hours per week on average.

- Developed highly complex CNC tool designs utilizing CAD software, significantly reducing design time from 10 hours to 6 hours per project while maintaining accuracy levels of 99%.

- Debugged computer programs related to automated machinery operations with an emphasis on trouble shooting errors at their source code level; lowered system failure rates by 30%.

- Compiled over 500 design specifications for a variety of tools and machines, resulting in the development of 10+ highly efficient models that improved production cycles by 20%.

- Reduced assembly time from 3 hours to 1 hour on average using innovative tool designs; saved $10K in labor costs over 6 months period.

- Documented all project details and results in engineering reports, including diagrams detailing the construction methods used for each prototype model produced.

- Substantially enhanced quality control processes through designing automated testing systems that ensured parts met requirements before installation into products or machinery; reduced defect rate by 15%.

- Demonstrated excellent mechanical aptitude when transforming traditional manufacturing practices into digital solutions with advanced automation capabilities; achieved 30% cost savings within one year of implementation.

- Constructed over 200+ automated tooling systems with precision, ensuring that all components and assemblies met the necessary safety requirements.

- Diligently managed a team of 8 engineers to develop detailed designs for new tools and improve existing ones; achieved an average reduction in production time by 14%.

- Calibrated mechanical parts such as gears, motors, linkages etc., utilizing CNC machines and CAD/CAM software programs; decreased manufacturing errors by 18%.

- Optimized cost-efficiency when selecting materials or designing 3D models for prototype testing purposes; reduced overall design costs by $5K in the last quarter.

- Fabricated various types of jigs & fixtures using manual lathes, millers and press brakes while adhering to strict quality control standards – resulting in zero customer complaints over two years of service delivery.

- Assembled and tested over 500 intricate tools and dies in accordance with engineering drawings, achieving a 95% successful rate of implementation.

- Assessed blueprints and inspected prototypes to identify potential design problems; successfully reduced the number of tooling revisions by 20%.

- Analyzed customer requirements and customized existing designs using CAD software for enhanced performance; improved efficiency by 30%.

- Programmed CNC machines for machining complex components according to specifications; completed projects on average 15 hours ahead of schedule.

- Efficiently managed inventory levels across all tooling departments, ensuring that sufficient resources were available at all times while reducing waste costs by $6,000 yearly.

- Mentored junior engineers in the design process of over 25 tools, resulting in a 20% increase in productivity.

- Structured and documented detailed tool designs for complex components while ensuring accuracy; reduced development time by 40%.

- Thoroughly analyzed customer requirements to create innovative designs that improved product performance and reliability at lower costs.

- Coordinated with cross-functional teams including manufacturing, quality assurance, operations and sales during prototyping activities for 10+ projects.

- Presented new engineering concepts to management team and customers; won 3 awards from industry peers for outstanding workmanship on redesigns of existing products within budget constraints.

- Achieved a 20% reduction in design costs by reengineering existing tools and developing new tooling solutions.

- Reorganized the design processes, resulting in a 25% improvement in time-to-market for all projects while reducing production delays by 30%.

- Facilitated meetings with clients to discuss their needs and expectations regarding tool designs; developed prototypes based on customer feedback that met or exceeded their requirements each time.

- Utilized CAD/CAM software as well as industry standard engineering practices to create detailed drawings, models and specifications of cutting tools, drill bits and other types of industrial equipment required for specific manufacturing applications.

- Reliably tested designed products under different conditions to ensure they met specified tolerances before being released into production; improved quality control measures which led to fewer product defects at inspection points (+20%).

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may be looking for a tool design engineer with experience in 3D printing, while Organization B may be seeking someone who is familiar with CAD and CAM software.

It is essential to keep this in mind because of the applicant tracking systems utilized by many companies. Their role is to analyze resumes for certain characteristics (such as specific keywords), filtering out the ones they deem not to be a high-quality match for that particular job.

Once listed here, you can further elaborate on your skillset by discussing it in more detail in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- 3D Printing

- Assembly

- CAD/CAM Software

- Design for Manufacturing (DFM)

- GD&T

- Machining

- Material Selection

- Prototyping

- Quality Control

- Reverse Engineering

4. Education

Adding an education section to your resume will depend on how much work experience you have. If you are just starting out and don’t have a lot of professional accomplishments, include the education section below your objective statement. However, if you already have plenty of relevant experiences to showcase, feel free to omit the education section altogether.

If an education is included in your resume, make sure to mention courses related to tool design engineering that demonstrate knowledge about this particular field.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They can also be used to show that you have kept up with the latest industry trends and best practices, which is something employers value highly.

When applying for jobs, make sure to include any relevant certifications on your resume so hiring managers know what qualifications you possess. This will help them determine if you are the right fit for their organization or not.

Certified Tool Design Engineer (CTDE)

Society of Manufacturing

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Judy Mosciski, this would be Judy-Mosciski-resume.pdf or Judy-Mosciski-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of the job application process. It is a document that provides recruiters with more information about yourself and why you are perfect for the role.

Cover letters typically consist of 2 to 4 paragraphs, separate from your resume. They give hiring managers insight into who you are as a person and how your skills fit in with their company’s goals and objectives. Even if it isn’t required by the employer, it is highly recommended that you submit one alongside your resume to increase your chances of securing an interview or job offer.

Below is an example cover letter:

Dear Irwin,

I am writing to apply for the position of Tool Design Engineer at XYZ Company. I am a Mechanical Engineering graduate with experience in designing and developing tools, dies, molds, jigs, fixtures, and gauges. I have also gained expertise in reverse engineering and 3D modeling using various software such as SolidWorks, AutoCAD, Pro/Engineer Wildfire 5.0, etc.

In my current role as a Tool Designer at ABC Corporation. , I am responsible for creating new tool designs as well as modifying existing ones. My job involves liaising with clients to understand their requirements, conducting research to come up with innovative solutions that meet their needs, and preparing detailed specifications and drawings of the proposed designs. I have successfully designed several complex tools that are currently being used in production by leading companies in the automotive industry.

I am confident that I can be an asset to your organization due to my technical skills as well as my ability to work independently or collaboratively as part of a team. Moreover, I possess good problem-solving skills which enable me to troubleshoot issues quickly and efficiently. Given an opportunity, I will put all my knowledge and experience to use for the benefit of your company.

Please find attached my resume along with this letter for your perusal. Should you require any further information about me or my qualifications; please do not hesitate to contact me at [phone number] or via email at [email address]. Thank you for taking the time out to consider my application today; I look forward eagerly towards hearing from you soon regarding this matter.

Sincerely,

Judy

Tool Design Engineer Resume Templates

Axolotl

Axolotl Fossa

Fossa Lorikeet

Lorikeet Gharial

Gharial Rhea

Rhea Ocelot

Ocelot Quokka

Quokka Pika

Pika Cormorant

Cormorant Kinkajou

Kinkajou Markhor

Markhor Bonobo

Bonobo Indri

Indri Numbat

Numbat Dugong

Dugong Hoopoe

Hoopoe Jerboa

Jerboa Saola

Saola Echidna

Echidna Rezjumei

Rezjumei