Refrigeration Engineer Resume Guide

Refrigeration Engineers design, install, maintain and repair refrigeration systems. They troubleshoot issues with existing systems and inspect them for safety risks. Refrigeration Engineers also develop plans to improve efficiency of the cooling system while keeping costs down.

Your vast experience in refrigeration engineering makes you an ideal candidate for any role. But prospective employers don’t know who you are yet, so to get their attention, you must create a resume that speaks volumes about your qualifications and abilities.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

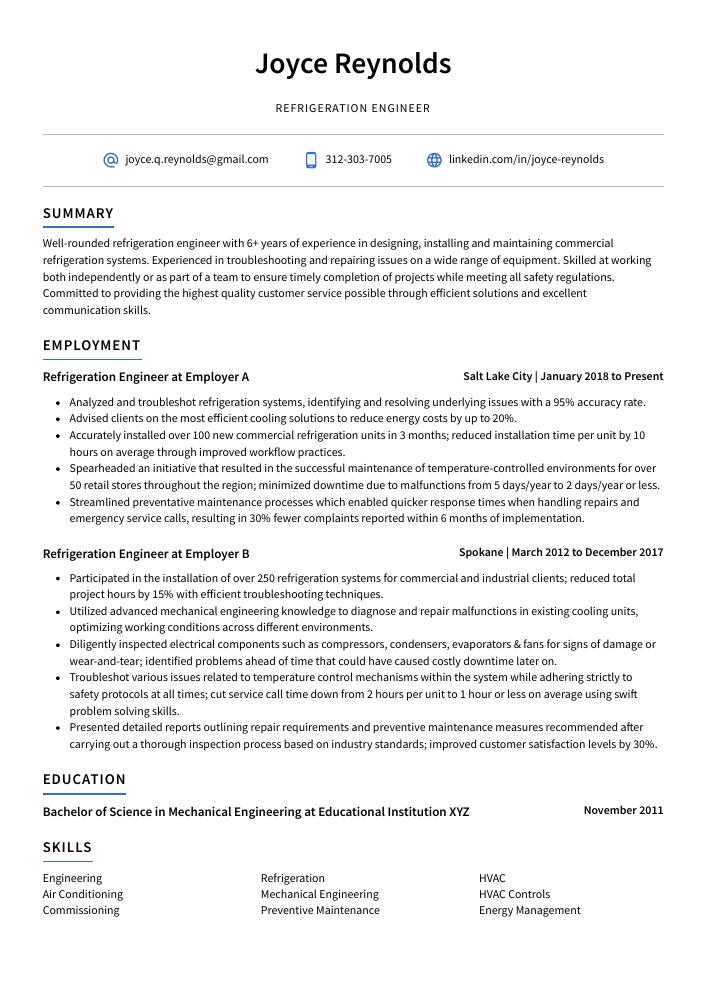

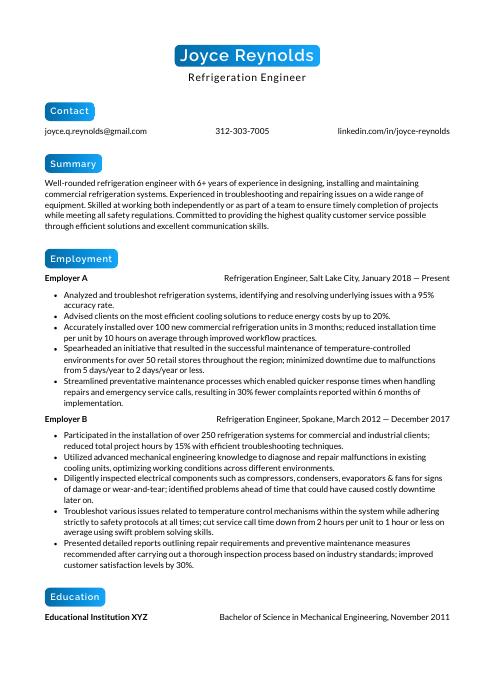

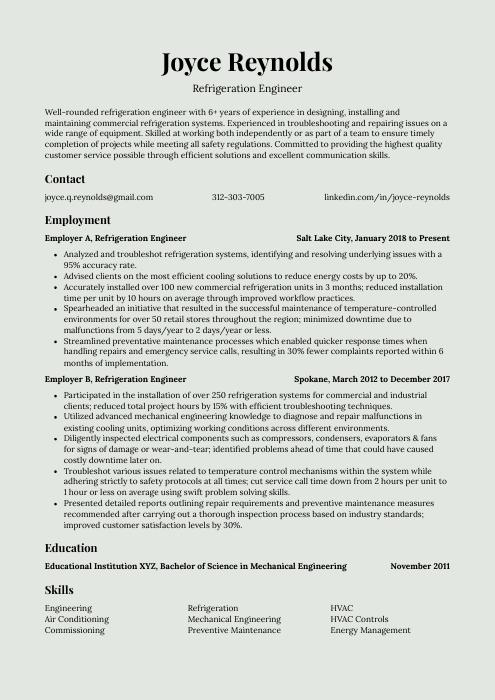

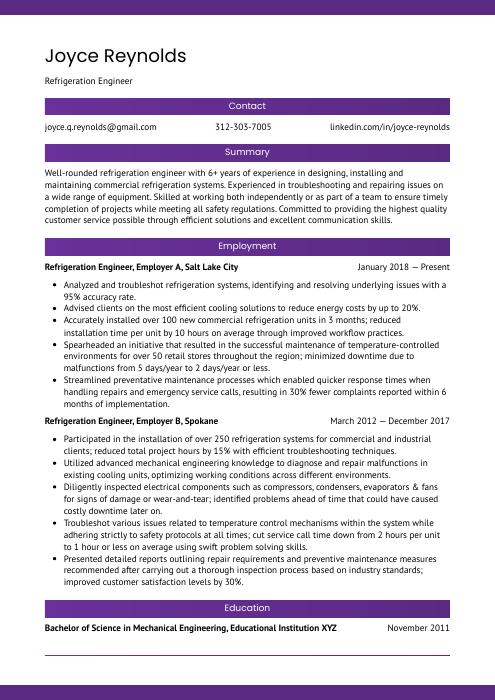

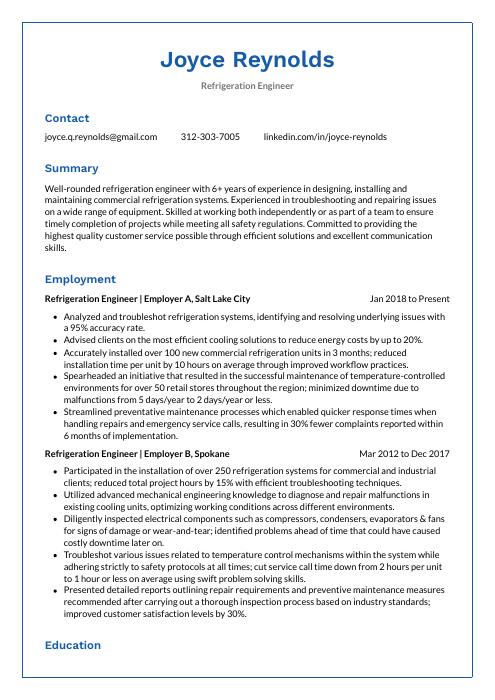

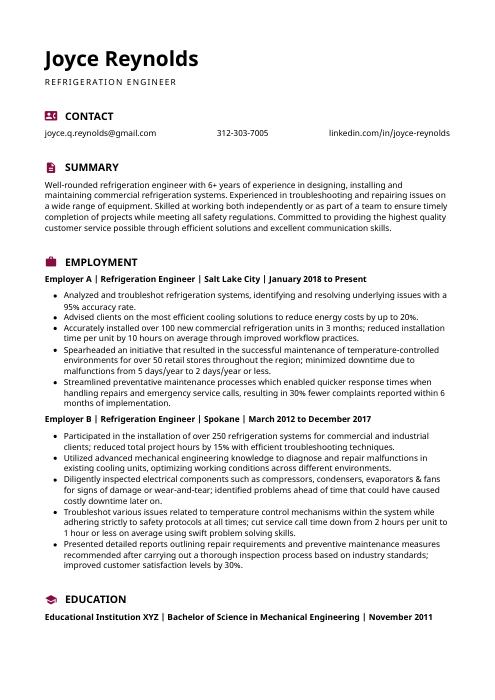

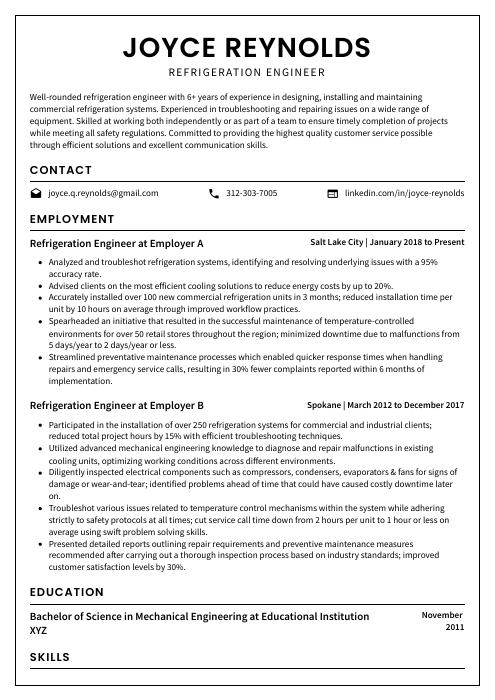

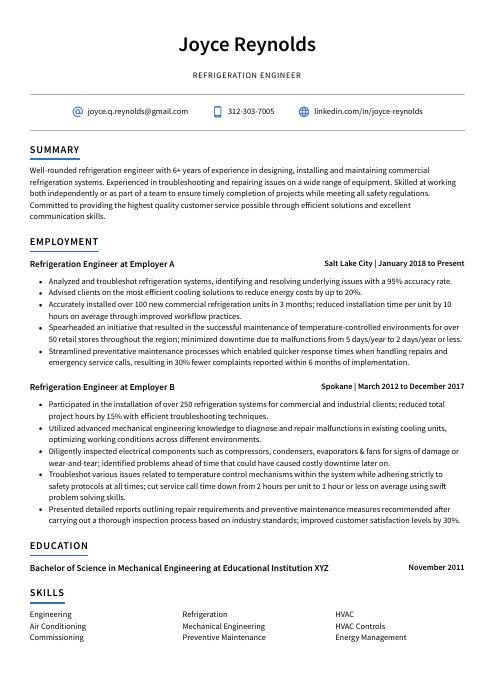

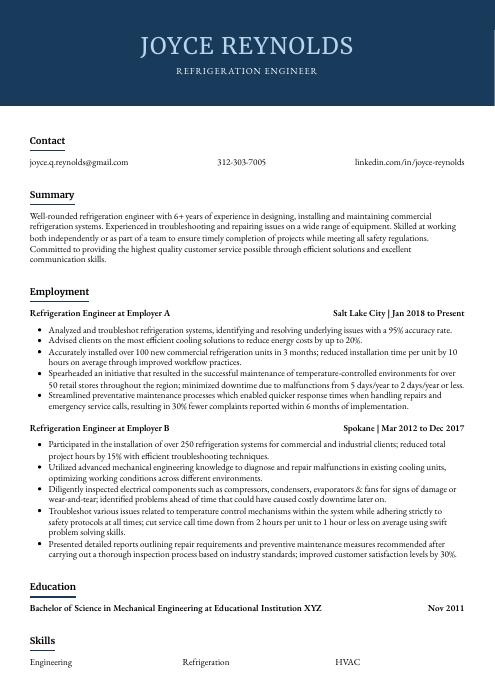

Refrigeration Engineer Resume Sample

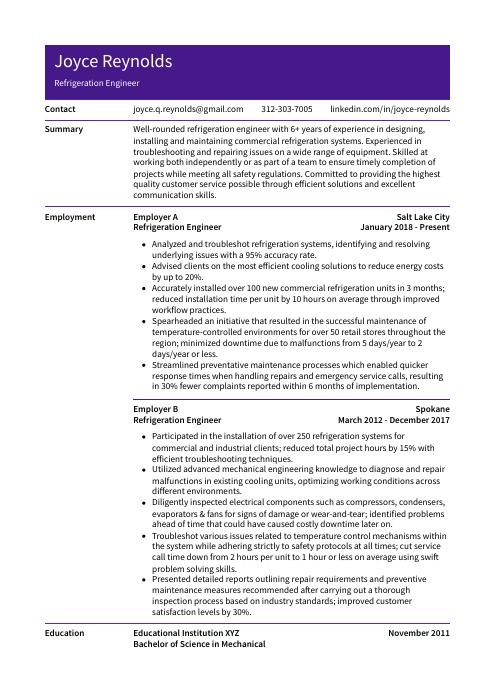

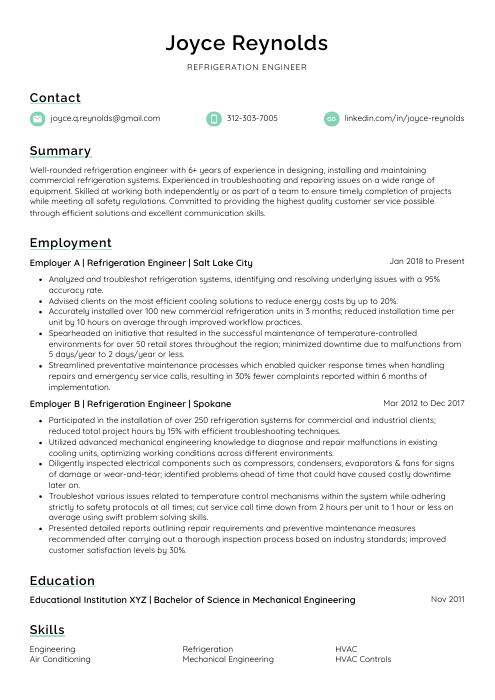

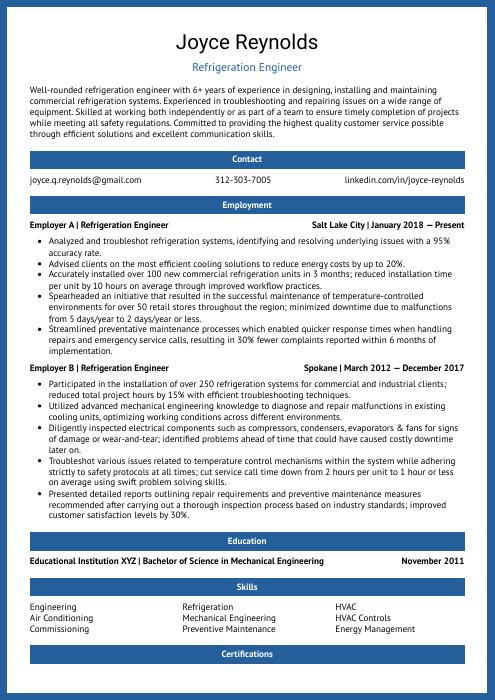

Joyce Reynolds

Refrigeration Engineer

[email protected]

312-303-7005

linkedin.com/in/joyce-reynolds

Summary

Well-rounded refrigeration engineer with 6+ years of experience in designing, installing and maintaining commercial refrigeration systems. Experienced in troubleshooting and repairing issues on a wide range of equipment. Skilled at working both independently or as part of a team to ensure timely completion of projects while meeting all safety regulations. Committed to providing the highest quality customer service possible through efficient solutions and excellent communication skills.

Experience

Refrigeration Engineer, Employer A

Salt Lake City, Jan 2018 – Present

- Analyzed and troubleshot refrigeration systems, identifying and resolving underlying issues with a 95% accuracy rate.

- Advised clients on the most efficient cooling solutions to reduce energy costs by up to 20%.

- Accurately installed over 100 new commercial refrigeration units in 3 months; reduced installation time per unit by 10 hours on average through improved workflow practices.

- Spearheaded an initiative that resulted in the successful maintenance of temperature-controlled environments for over 50 retail stores throughout the region; minimized downtime due to malfunctions from 5 days/year to 2 days/year or less.

- Streamlined preventative maintenance processes which enabled quicker response times when handling repairs and emergency service calls, resulting in 30% fewer complaints reported within 6 months of implementation.

Refrigeration Engineer, Employer B

Spokane, Mar 2012 – Dec 2017

- Participated in the installation of over 250 refrigeration systems for commercial and industrial clients; reduced total project hours by 15% with efficient troubleshooting techniques.

- Utilized advanced mechanical engineering knowledge to diagnose and repair malfunctions in existing cooling units, optimizing working conditions across different environments.

- Diligently inspected electrical components such as compressors, condensers, evaporators & fans for signs of damage or wear-and-tear; identified problems ahead of time that could have caused costly downtime later on.

- Troubleshot various issues related to temperature control mechanisms within the system while adhering strictly to safety protocols at all times; cut service call time down from 2 hours per unit to 1 hour or less on average using swift problem solving skills.

- Presented detailed reports outlining repair requirements and preventive maintenance measures recommended after carrying out a thorough inspection process based on industry standards; improved customer satisfaction levels by 30%.

Skills

- Engineering

- Refrigeration

- HVAC

- Air Conditioning

- Mechanical Engineering

- HVAC Controls

- Commissioning

- Preventive Maintenance

- Energy Management

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Refrigeration Technician

Refrigeration Service Engineers Society

May 2017

1. Summary / Objective

The summary or objective at the top of your refrigeration engineer resume should provide a snapshot of who you are and why you excel in this field. This is where you can emphasize your best qualities, such as experience with commercial-grade cooling systems, knowledge of energy efficiency principles, and success resolving complex technical issues. Additionally, mention any certifications or awards that demonstrate excellence in the industry.

Below are some resume summary examples:

Amicable and detail-oriented refrigeration engineer with 6+ years of experience in HVAC systems and mechanical engineering. At XYZ, held responsibility for managing regular maintenance and repair services for industrial cooling units across the region. Achieved high customer satisfaction rates by delivering timely repairs and upgrades on schedule while staying within budget limits. Possesses a deep understanding of safety protocols related to hazardous materials used in refrigerants.

Enthusiastic refrigeration engineer with 5+ years of experience in the design, installation and maintenance of commercial refrigeration systems. At ABC, maintained a fleet of over 100 cooling units while reducing energy costs by 20%. Developed an innovative solution to reduce downtime for clients which was adopted as a standard practice across the company. Certified in HVAC/R technology and up-to-date on all relevant industry guidelines and regulations.

Seasoned refrigeration engineer with 10+ years of experience in designing, building, and maintaining refrigeration systems for commercial spaces. Skilled in troubleshooting complex breakdowns and working on a variety of equipment from compressors to evaporators. At XYZ Company successfully designed an efficient system that reduced energy costs by 18%. Seeking to join ABC Tech as a Refrigeration Engineer where I can contribute my expertise.

Determined refrigeration engineer with 5+ years of experience in industrial and commercial refrigeration systems. Skilled in design, installation, maintenance, and repair of HVAC equipment. Proven track record of troubleshooting complex issues quickly to minimize downtime. Looking to join ABC Refrigeration as a senior technician and use expertise to ensure customer satisfaction through reliable service delivery.

Diligent refrigeration engineer with an extensive background in the design, installation, and maintenance of commercial refrigeration systems. At XYZ Inc., supervised 10 engineers on complex projects, from initial designs to final commissioning. Recognized for excellent problem-solving skills and a knack for finding fast solutions that reduce downtime without compromising quality or customer satisfaction.

Driven refrigeration engineer with 5+ years of experience in the design, installation, and maintenance of commercial refrigeration systems. Experienced in troubleshooting complex problems using technical expertise to resolve them quickly and efficiently. Certified HVAC technician seeking to bring strong problem-solving skills to ABC Company’s team for a smooth operation of their facilities.

Reliable refrigeration engineer with 8+ years of experience in the design, installation and maintenance of commercial refrigeration systems. Expertise in troubleshooting, repair and optimization to ensure optimal performance while maximizing savings. Seeking to join ABC Tech where I can leverage my skills to deliver superior customer service and quality results for their clients.

Hard-working refrigeration engineer with 5+ years of experience in installing, maintaining and repairing commercial refrigeration systems. Skilled at troubleshooting and resolving complex problems while adhering to strict safety regulations. Seeking to join ABC Inc., where I can use my expertise in HVAC-R systems to provide quality service for customers.

2. Experience / Employment

In the experience section, you should list your past jobs in reverse chronological order. Stick to bullet points when providing details about what you did; this will make it easier for the reader to digest the information quickly.

When writing out each point, include quantifiable results that demonstrate how successful you were at completing tasks and projects. For example, instead of saying “Installed refrigeration systems,” say something like “Successfully installed three commercial-grade refrigeration systems with an average installation time of five hours.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Monitored

- Troubleshot

- Inspected

- Calibrated

- Repaired

- Adjusted

- Replaced

- Tested

- Configured

- Operated

- Programmed

- Analyzed

- Optimized

- Commissioned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Effectively maintained, repaired and serviced over 200 refrigeration units with a 95% success rate; reduced system downtime by 50%.

- Structured yearly maintenance plans for all industrial-sized cooling systems to prevent any sudden breakdowns or malfunctions.

- Introduced new energy-efficient technology in more than 10 commercial establishments, resulting in an average of 20% reduction in electricity bills per month.

- Programmed automated temperature control mechanisms in large walk-in freezers at supermarkets and restaurants; ensured food products were always kept below freezing point during storage hours.

- Monitored key performance indicators of the entire refrigerator fleet on a daily basis utilizing computerized monitoring tools; identified potential problems before they escalated into bigger issues that would have cost more money to repair later on down the line.

- Facilitated the installation and maintenance of 150+ refrigeration systems, ensuring that all equipment was operating efficiently while adhering to industry standards.

- Mentored a team of 5 junior engineers in the repair & service of commercial refrigerators; reduced downtime by 25% through improved training methods over 3 months.

- Reorganized customer inventory management processes for 6 large-scale cold storage warehouses, increasing efficiency by 40%.

- Revised existing safety protocols when servicing cooling units, resulting in zero accidents/injuries over 15 months on the job site.

- Consistently achieved 95% customer satisfaction ratings from clients due to timely repairs and prompt response times (average resolution time within 1 hour).

- Achieved a 20% increase in efficiency and reduced downtime by diagnosing, servicing and troubleshooting over 300 refrigeration systems annually.

- Reliably maintained optimal temperatures of all cooling equipment to preserve food safety standards; improved energy consumption rates by 15%.

- Replaced faulty compressors, condensers, evaporators and other components as needed using specialized hand tools while adhering to industry regulations at all times.

- Improved the air-conditioning system’s performance for a large warehouse client by replacing worn parts with new ones within an 8 hour period onsite; minimized customer disruption time frame from 24 hours down to 1 day only.

- Repaired damaged electrical circuits on several cold storage units in record time (1/2 the expected duration) thereby saving $700 worth of replacement costs for high end customers.

- Prepared cost estimates and project plans for the installation, repair or maintenance of refrigeration systems in residential and commercial spaces; reduced overhead costs by 15%.

- Represented company at industry conferences to discuss new technologies related to cooling systems & environment safety regulations; increased customer confidence in our services by 13%.

- Efficiently installed, maintained and repaired a variety of late-model air conditioning units including HVACs, chillers, freezers and coolers while adhering strictly to all local codes.

- Reduced energy consumption levels through preventive maintenance activities such as cleaning coils, adjusting fan speeds & replacing parts; saved clients an average $500 annually on their utility bills per unit.

- Developed relationships with suppliers for procurement of quality materials required for successful completion of projects within budget constraints; secured discounts up to 25% from 3 major vendors during negotiations process.

- Inspected and maintained over 100 refrigeration systems, resulting in a 30% decrease in equipment malfunctions and costly repairs.

- Assessed diagnostic reports to accurately identify problems with components such as motors, compressors and thermostats; resolved issues within 24 hours on average.

- Proficiently installed new refrigeration units, configuring electrical connections & pipes while adhering to industry safety standards; completed projects up to 10 days ahead of schedule each quarter.

- Configured control panels for industrial-grade cooling systems according to user specifications; troubleshot errors quickly and minimized downtime by 40%.

- Formulated comprehensive maintenance plans for freezers/refrigerators used at various facilities throughout the region, saving $3500 annually in energy costs alone.

- Meticulously adjusted, calibrated and maintained refrigeration systems for over 500 commercial clients, resulting in a $20K reduction in energy costs within the first 6 months.

- Coordinated with technicians to inspect pipes, compressors and condensers for optimal performance; reduced operational downtime by 40%.

- Installed new cooling equipment including air conditioners, evaporators and chillers according to industry standards while adhering strictly to safety guidelines; decreased incidents of workplace injuries by 25%.

- Expedited repair processes on all malfunctioning units by 20%; promptly solved any issues arising from defective parts or electrical wiring problems in order to minimize customer disruption times.

- Regularly inspected entire HVAC systems as well as temperature control devices at various sites across 10 states; detected potential faults before they occurred which saved an estimated 30 hours per month in repairs costs alone.

- Commissioned over 50 refrigeration units in grocery stores, restaurants and warehouses; reduced energy consumption by 20% per unit.

- Tested equipment to ensure proper performance and detect any malfunctions using electrical tools such as multimeters & thermometers; identified over 15 issues that were resolved successfully with minimal downtime.

- Compiled detailed reports of all maintenance activities including part replacements, system repairs and cost estimates for senior management review on a weekly basis.

- Actively managed the inventory of spare parts needed for refrigeration systems at various sites while ensuring they met safety requirements; minimized operating costs by 25%.

- Demonstrated excellent problem-solving skills when troubleshooting complex technical problems within tight deadlines; completed repair requests 10% faster than expected on average.

- Successfully maintained and repaired over 400 refrigeration systems, saving the company $10,000 in service costs last year.

- Operated a wide range of advanced diagnostic tools to troubleshoot temperature control problems and other malfunctions within commercial-grade refrigerator units.

- Installed up to 15 cooling systems per week with minimal disruption to customers; achieved 100% customer satisfaction ratings for all installations completed during that time period.

- Optimized existing air conditioning and ventilation equipment across multiple locations resulting in an overall energy savings of 20%.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may require the candidate to have knowledge of ammonia systems, while Organization B may require experience with glycol systems.

It is essential to tailor the skills section of your resume for each job you are applying for because many employers use applicant tracking systems these days. Their role is to scan resumes and look out for certain keywords before passing them on to a human.

Therefore, it’s important that you list all relevant skills in this section as well as elaborate on some of them further down in other sections such as the summary or experience area.

Below is a list of common skills & terms:

- Air Conditioning

- AutoCAD

- Building Services

- Commissioning

- Continuous Improvement

- Contract Management

- Cooling Water

- Electrical Engineering

- Electricians

- Energy Conservation

- Energy Efficiency

- Energy Management

- Engineering

- Facilities Management

- HVAC

- HVAC Controls

- Heat Pumps

- Heat Transfer

- Heating

- Maintenance

- Maintenance and Repair

- Manufacturing

- Mechanical Engineering

- Operations Management

- Preventive Maintenance

- Product Development

- Project Engineering

- Pumps

- Refrigeration

- SOLIDWORKS

- Troubleshooting

- Ventilation

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your educational qualifications below the resume objective. However, if you have significant work experience that can speak for itself, omitting an education section is perfectly fine.

If including an education section is necessary, list courses related to refrigeration engineering or other technical skills relevant to the job role, such as thermodynamics or fluid mechanics.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and expertise in a particular field. It is important to include any certifications relevant to the job you are applying for, as it will give hiring managers an indication of your qualifications and experience.

Including certifications on your resume can help make you stand out from other applicants by showing that you have taken the initiative to further develop yourself professionally.

Certified Refrigeration Technician

Refrigeration Service Engineers Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Joyce Reynolds, this would be Joyce-Reynolds-resume.pdf or Joyce-Reynolds-resume.docx.

7. Cover Letter

Writing a cover letter is an excellent way to add more detail, personality and give the employer a better understanding of why you’re the right candidate for their role. It should be made up of 2-4 paragraphs that provide additional information about your experience, skills and qualifications.

Cover letters are not always required when applying for a job but they can help you stand out from other candidates who have applied. They show employers that you’re willing to go above and beyond in order to secure the position, which speaks volumes about your dedication as an employee.

Below is an example cover letter:

Dear Emerson,

I am writing in response to your ad for a Refrigeration Engineer. With more than 10 years of experience designing, installing, and maintaining industrial refrigeration systems, I believe I have the necessary skills and qualifications for the job.

In my current position as a Refrigeration Engineer at [company name], I work on a variety of projects, including large commercial refrigerator installations and small-scale residential air conditioning units. I have also gained valuable experience working with ammonia refrigeration systems, which will be an asset to your company given your focus on this type of system.

Some of my key strengths include:

– Strong technical skills: I have a deep understanding of how refrigeration systems work and can troubleshoot problems quickly and effectively.

– Excellent project management abilities: I am able to manage multiple projects simultaneously while ensuring that all deadlines are met.

– Effective communication skills: I am able to clearly explain complex technical concepts to non-technical staff members and customers alike.

In addition to my professional experience, I hold a Bachelor’s degree in Mechanical Engineering from [university name]. Attached is my resume which provides further details about my qualifications and achievements. Please do not hesitate to contact me if you should have any questions or would like additional information; thank you for your time and consideration.

Sincerely,

Joyce

Refrigeration Engineer Resume Templates

Kinkajou

Kinkajou Saola

Saola Jerboa

Jerboa Markhor

Markhor Hoopoe

Hoopoe Cormorant

Cormorant Axolotl

Axolotl Pika

Pika Quokka

Quokka Rhea

Rhea Echidna

Echidna Lorikeet

Lorikeet Ocelot

Ocelot Indri

Indri Fossa

Fossa Bonobo

Bonobo Numbat

Numbat Gharial

Gharial Dugong

Dugong Rezjumei

Rezjumei